View our KOV seating metalworking facilities

20. 02. 2023

At LD Seating we try to be as self-sufficient as possible and for most of our production to take place on a single location. As a result, our manufacturing operations and logistics are simpler and our impact on the environment, in terms of road transport, is lower. That is why we have got our own painting line and founded two sister companies: PUR seating, which makes foam shells as well as other parts for our chairs and armchairs; and KOV seating, which we would like to introduce to you.

KOV seating was founded to make metal components for our products. It manufactures the frames of our conference chairs, different pads, mechanical parts and wire inserts – the load-bearing structures that are the basis of the chair shells filled with foam.

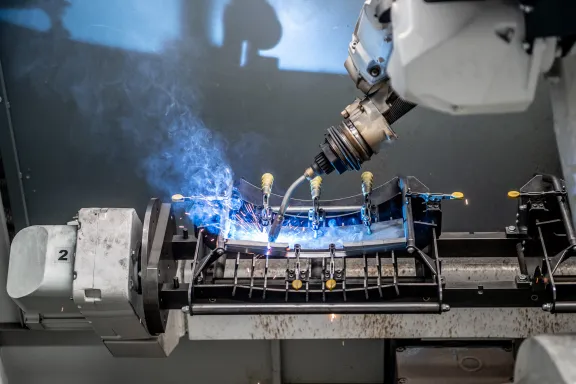

Our metalworking facilities are very well equipped: we have, for example, a 3D tube bender and a welding robot. Thanks to that we can quickly respond to our customers’ needs and significantly minimise our stock supplies.

At KOV seating we manufacture the four-legged frames for the SEANCE, TRIVI and SPOT series, the backrests for the ELEMENT and WEB OMEGA series, and other products. One example proving that we try to be as self-sufficient as possible is our MELODY MEETING 360-N chair, which is completely made in our own facilities. The insert and legs are made by KOV seating, the shell is foam moulded by PUR seating, the covers are sewn by our seamstresses, the upholstery work is done in our own workshop and the legs are painted in our own painting shop.

Gallery

What's new

New Quadra series

Our range has a new addition: the Quadra series. It includes one-, two- and three-seat versions designed with focus on comfort and versatility. Typical features of the Quadra are rectangular shapes with finely rounded edges and slim metal legs, whic...